Not Your Every-Day Power Tool

14 August 2011 20:20 Filed in: Tools

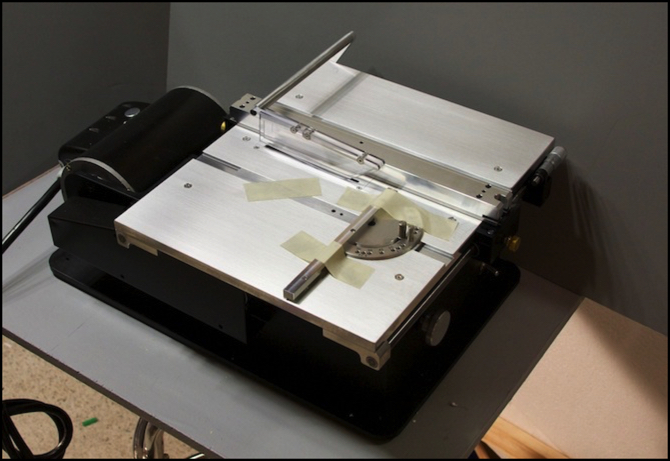

As I mentioned a couple of weeks ago, I’ve been waiting for a new saw to continue work on the Expressway. It arrived this week, and while I haven’t done much with it yet, what I have done is living up to my expectations. The saw, shown above as I was unpacking it, is a Byrnes saw. This is made by a modeler, for modelers, and intended for accuracy, as well as the ability to cut small pieces of wood or plastic (with the right blade, thin aluminum, brass or other soft metals would probably be fair game also). It’s not cheap, but it’s worth the money, at least to me.

The top is machined from a chunk of aluminum 10” x 12”, and the base appears to be aluminum also (as are the bulk of the accessories). Several options are available: I added the extension to the rip fence (above to right of blade) that makes it about 1/2” thick instead of just a few mm (this is removable) and added the extended-length arm to the miter (seen taped down above). I also added the metric version of the micrometer (right corner) that can be used to advance the fence for cutting precise-width strips of material, and I bound the “Rip Taper Jig” which is another accessory for holding things at a specific angle for cutting.

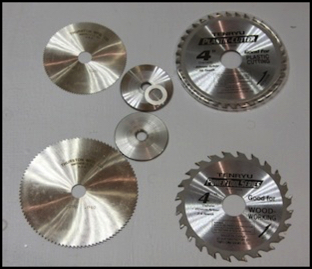

The saw comes with a 24-tooth carbide blade suitable for cutting wood. Several others are available. The saw can take 3” and 4” blades with 1/2” and 20mm arbors; the actual arbor shaft is 3/8”, and other arbors are available on request. I bought several blades with the saw, expecting to do some experimentation. However, the one I thought most likely to be of use turned out to work as expected, so I’ll be doing most of my work with that.

3” and 4” Saw Blades

The saw blade can be height-adjusted, but not tilted. A tilted table-top add-on is available for people who need that capability, but I don’t. The motor is below the level of the table-top, and the blade guard and its support can be removed for cutting larger items that overhang the edge of the table (the fence is not easily removable so you can only overhang on one side). The aluminum insert around the blade is screwed in place, and can be replaced with “zero-clearance insert” blanks so you can make a zero-clearance insert for any blade, which is useful for minimizing flex (and thus chipping) in very thin stock.

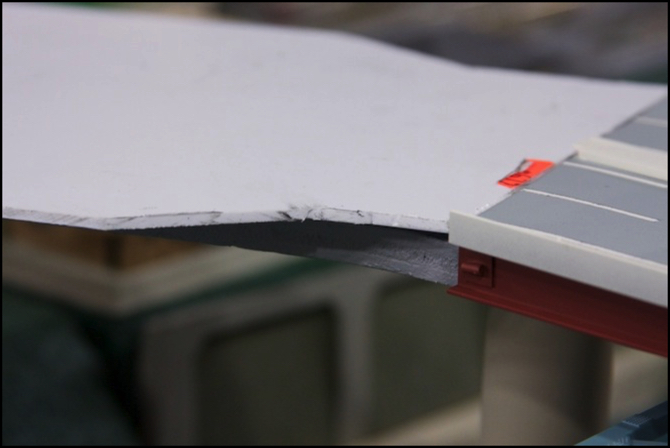

My chosen blade is a “slitting saw”, which is a narrow steel blade without carbide tips or other elaborations, intended for cutting thin stock with a minimum of wasted material. I bought the one advertised as a 3”, 80-tooth 0.020” kerf (cut width) blade, which at least in my case turned out to be a Thurston I-291 110-tooth (12tpi) blade. The manufacturer calls it a “cutting saw” but other sites describe it as a type of slitting saw. Regardless, it cuts sheet styrene quite well (at least thicker sheets, I haven’t tried thin stuff yet) without chipping or melting. I did use a zero-clearance insert for this.

Close-up of 2mm (0.080”) styrene cut with saw (no cleanup; this is straight from the saw)

I’ve added a number of photos of the saw to the Construction photo album. I’ve also added a page about the saw, and any additional experiences of note will be added there.

Website Conversion Update

Conversion of the pages from iWeb is going well, and I’m thinking I’ll make the change in two weeks. By then I’ll have all Musings and most of the major pages converted, but there will probably be a couple-dozen lesser pages left behind, which will either be converted later or rewritten as some of them are badly out of date and need significant clean-up. When I do switch to the new software, unfortunately most of the pages will have their URLs change (iWeb uses a flat structure, and RapidWeaver uses a hierarchical structure of directories if you organize things, which I am, which adds a directory name in front of the page name, making matching URLs very difficult). I should be able to keep Home the same, and if at all possible I’ll add a redirect for the top-level Musings page, but most will change.

I also haven’t worked out what I’m doing for blog comments or RSS feeds yet, but both will change from the current system (hopefully those will be improvements). Comments may be unavailable for a couple of weeks after the switch, while I research options (something I can’t easily do in advance since I’m changing hosting providers and at least one option I’m looking at depends on the choice of provider; and also because I want to actually try solutions out and see how they work).

Other website changes:

With the page conversion going on I haven’t really been adding to the website this summer, other than the brief comments in each Musing. As noted above I did add a page about the saw and that motivated me to also add a (presently lightly populated) page about other tools I’d been meaning to add for months; the latter probably won’t get more content until after the big switch).

=== Comments from the old system:

Tuesday, August 16, 2011 - 01:26 AM

quinntopia

Nice piece of hardware. That is the sort of thing I could, and would use, a lot. Tempting.