Airbrush I - Compressors

07 November 2013 23:35 Filed in: Tools

How NOT to Airbrush

About fifteen or twenty years ago I bought my first airbrush, I forget exactly when. It was (and still is, see above) a Badger 350 (current retail about US$45). Shortly after, I bought a cheap, simple compressor: a Badger Whirlwind 80-2 (no longer sold). The compressor puts out 0.4 cfm at 20 psi. It wasn't really a very good choice of compressor, being both noisy and underpowered, but it served well enough for what I did, at least at first.

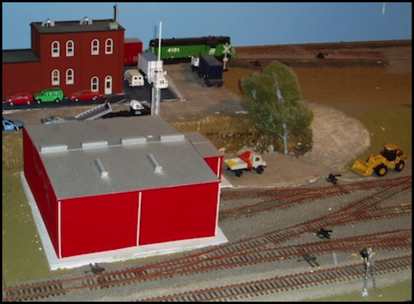

An airbrush is a very useful tool for modelers, and you don't need to be an artist to use one (I certainly am not!). My first use was to paint the rails of my HO flex-track "rust" after it was nailed down to the cork (yes, I was still using nails). To do that you just spray a 2" (5 cm) wide swath of color before ballasting, masking off whatever you don't want painted, and then wiping the tops of the rail with a cloth lightly soaked in thinner before the paint can set. I had to mix my own rust color, which turned out to be easy. The 'brush worked so well, and so intuitively, I was sold. I also used it for painting large swaths of color on plastic buildings. In the photo below, the brick building, as well as both the roof and sides of the red building, and the rails of the track were all painted with my airbrush.

Original HO layout, c. 2004

But ultimately, I stopped using it. There were several reasons, but among them were problems when I tried to change from lacquer paint (the old highly-toxic Floquil formula) to heavier enamel or acrylic paints. I just couldn't get it to coat well. Eventually I decided that the compressor was the problem, but never got around to replacing it.

I've decided to get back into using an airbrush. Today's post is the first of at least two. This one will focus on compressors and my research into what I want to get. I'm also going to get a new airbrush, and that will be the focus of a later post.

Issues, Considerations and Alternatives

My old compressor produces 0.4 cfm at 20 psi (0.2 l/s @ 138 kPa). I've read that 0.5 cfm at 20psi is an acceptable low-end level, but most online recommendations suggest more pressure is needed. That's certainly my experience. Iwata, a manufacturer of both airbrushes and compressors, says you need at minimum 0.5 cfm at 30psi. Some online posts suggest that even more pressure, 35 or even 40 psi, can be required for some paints used by modelers (people working with really heavy paint, like for t-shirts, need even more, while people using airbrushes for makeup or tanning need much less).

A compressor also needs to be rated slightly above the pressure you want at the brush, as you'll adjust it down with a regulator and you need some margin for that to work. Thus if my brush pressure could be as high as 30 psi, I probably should get a compressor that puts out 35 psi or more. If I want to brush at 40 psi, the compressor should be rated for 45 psi or higher.

The cfm rating doesn't seem to be as important. Most compressors produce between 0.5 and 1.0 cfm, and many do more; I've read that you only need 1 cfm if you're using a spray gun rather than an airbrush. So for modeling purposes, you probably need to focus on the psi rating, and avoid the really low-end models, which are really aimed at specialized uses and don't put out enough pressure for modeler’s paints. However, a model with very low cfm could be a concern.

There are alternatives to buying a compressor: air tanks you fill at a garage or welding-supply shop, or a home-made compressor/tank system (some people make these from refrigerator compressors). Just don't use "canned air", the results will be very disappointing: pressure will drop quickly as the can cools, and the airbrush won't work very well, and you'll empty the can with very little to show for it. This gets expensive fast, as well as being very frustrating.

Unfortunately a lot of cheap "beginner" kits are sold with canned air adapters, implying that this is a good way to start. It isn’t. I started that way, and nearly gave up on airbrushing before I learned how easy it was. But I bought a compressor, and even though it wasn't a very good one, it was so much better than canned air that there's really no comparison.

So, I'm going to get a compressor that represents an improvement over my original one, as part of my plan for making more use of the airbrush in my modeling. And specifically, I’m going to get one made for airbrush use and equipped with a tank. That still leaves quite a number to choose from. But before I get to that, let me lay out why I'm not doing something else.

Paths Not Taken

I'm not using a refillable tank, because I don't have any gas stations nearby with free air, and because I don't want to be running out to refill the tank anyway. Even if the air was free, my time is worth more. And the air's unlikely to be free.

I'm not building my own, because my hobby isn't building compressed-air equipment; I want to play with trains. Or build models. Or play with electronics and software. I’ve got enough hobbies, I don’t need another one.

And I'm not buying a commercial compressor designed for air tools or spray guns, although they can work quite well for airbrushing, because they tend to be noisy, and I live in an apartment with thin walls and I work on the layout at night. Also, you need to do a bit of work to adapt the fittings to airbrush fittings, and while I'm sure I could figure it out without too much effort, see the point above about what my hobby isn't.

Also, I’m buying well above the minimum I could get, because I want flexibility to grow into the compressor and to not have to replace it five years from now. If you want a solid entry-level compressor, Badger’s TC908 (40 psi, regulator, gauge and moisture trap, US$162 typical retail) or Paasche’s D220R (50 psi, regulator, gauge and moisture trap, US$130) are both very solid tankless compressors with enough power to get the job done well. Just don’t go cheap with a 20 psi “beginner’s” compressor like I did; you’ll almost certainly regret it.

Paasche D220R

Compressor Requirements

As noted above, 35 psi is a good minimum output rating for a compressor (I'm using psi because most of the information I found online is in psi; for metric users, 35 psi equates to 2.4 bar or 240 kilopascals). But this actually depends on what kind of paint you use, and what kind of airbrush. An airbrush with a 0.2mm nozzle could get by with lower air pressure than one with a 0.3mm nozzle, while a 0.4mm nozzle would need more. The thicker the paint, the more pressure is required.

All of this is really about how much airflow across the nozzle is required to properly atomize the paint. Too little, and large chunks of color will "spatter" on the surface being painted, too much and you'll blow the paint off the model before it can dry. So that 35 psi number has some assumptions built into it, and exactly what they are isn't clear. If you paint with thin, light paint (my old lacquer paint) a 20 psi compressor will probably work. I want flexibility, both in paint and in future choice of nozzle size as I learn more about painting, so I'm going to be conservative and look for more pressure, using the 35 psi number as a baseline.

One thing I've noticed is that the rated psi numbers for compressors don't align with the min/max specifications for the compressor shutoff (something that really only matters if you have a tank). I suspect the nominal number is based on a specific cfm airflow, that likely varies, and that these numbers aren't providing a good apples-to-apples comparison. I’ll list the rated valued below, but I'll also list the min/max shutoff numbers where I have them, and the “min” is probably a better metric to use. As long as that’s above 35psi, the compressor should be adequate.

Having established that one requirement is a compressor putting out 35psi or more, what other requirements are there? Well, noise for one. As mentioned, I don't want to wake the neighbors at 1 AM when I decide to paint a model.

My old Badger was loud. I've seen it described as having a sound level of 56dB. Mine was louder than that. Enough so as to be annoying. You can't really get below 50dB without paying crazy amounts of money or getting a too-small compressor, but 50dB (quiet conversation level) would be fine.

Most models, unfortunately, do not provide specifications for sound levels. The ones that do are all under 60 dB, usually around 50 or 55 dB. So not quite as quiet as I might like, but in the vicinity, assuming those numbers are more accurate than mine was.

Note that 60dB is the sound level of a television 1 meter away, 50dB is “rainfall”, and 40dB is the level made by a refrigerator.

A third requirement is a tank. Not everyone needs one, but there are benefits. First, a tank is usually pressurized to 40 - 80 psi. This allows the compressor to run for a short time, and then turn off. It won't turn on again until the pressure drops too low. A compressor that isn't running is the quietest compressor of all. It will also last longer (less wear and tear, less overheating). Tanks also let the air cool after being compressed (compression heats air), as the air cools, water condenses out, making the moisture trap (see below) more effective. And they even out "pulsations" in the air pressure caused by the piston in the compressor (opinions online are divided as to how much of a problem this really is).

Paasche D3000R, with tank

Finally, I'm going to get an oil-free model, because they're less work to maintain than one that needs its oil changed periodically. Some people worry about oil getting in the paint, but you can deal with that with a filter. Some of the best compressors use oil, because it lets them run longer and quieter. But most hobbyist-priced compressors are oil-free designs anyway, which suits me.

Incidentally, some compressors come in an open-ended metal case. This provides a convenient surface for switches, and is said to reduce the noise level (although I have my doubts), but it’s mostly a cosmetic touch, to hide all the plumbing from casual view.

Accessories

There are some things you need to get with a compressor. Most of these likely come with it, but its useful to know what to look for, particularly with economy models.

First, you need a regulator with a pressure gauge. If your budget is really tight, you can get a simple regulator without a pressure gauge (a "bleed valve" type) and adjust by feel, but that adds extra work when you need to adjust for a different paint, as you can't say “oh, this needs 25psi rather than 30psi” and set a knob, but instead have to try spraying paint on scrap plastic or something at different settings each time. The gauge doesn't add a lot of cost, and there's a significant convenience there.

Second you need a moisture trap. This is usually attached to the regulator on typical hobbyist airbrush compressors (you can also get inline models). Compressing air creates condensation, and water in your air becomes water in your paint, which makes for spots messing up your nice, even, colors. Many people recommend putting a second water trap inline at the airbrush itself, because this will catch additional condensation formed as the air cools while going through the hose to the airbrush. That's particularly important if you live in a place that gets very humid.

Finally, you need a hose. Typically these are about 10' (3m) in length, and you're better off with the braided cloth kind than the cheap vinyl tubing sold with entry-level gear. A long hose helps even out airflow (not an issue if you're using a tank), cool the air (so that second moisture trap can work better), and lets you tuck the compressor under your workbench, so it's less noisy (for you anyway). You may want to equip the hose with quick-release fittings, but that's something I'll cover when I discuss airbrushes.

Choices, Choices, Choices

There are a number of big brands in this field: Badger, Iwata, and Paasche in particular, as well as a number of less well-known brands.

For my purposes, some candidate models (all prices typical retail online):

Note: my criteria for inclusion was tank compressors from well-known brands, which got good reviews by people who seemed to know what they were talking about (I mean real reviews, not those paragraphs on store sites). Consistent quality doesn't always go with brand names, but they help. I'm sure I'm overlooking a lot of reasonable contenders, but I'm aiming to minimize risk, not maximize choice.

I’m including the Paasche D3000R in this list as it’s popular among hobbyists, but I think it falls below my minimum criteria due to rated air pressure. This means that I’m going to be paying $240 or more for a compressor.

- Badger TC910 Aspire Pro, US$240, 57psi, 0.81cfm, 3 liter tank, 60dB*

- Iwata Smart Just Plus IS-875HT, US$363, 60psi, 1.4cfm, 0.45l tank

- Iwata Power Jet Pro IS-975, US$446, 60psi, 1.2cfm, 2l tank, 55dB, dual-piston, dual-regulator

- Iwata Power Jet IS-900, US$517, 60psi, 1.2cfm, 3.5l tank, dual-piston

- Paasche D3000R, US$160, 30psi**, 0.5cfm, 3.8l tank, 45dB

- Paasche DC600R, US$270, 55psi, 1.2cfm, 3.5l tank, 55dB (or 47dB, depending on source)

- Sparmax TC-620, US$330, 45psi, 0.875cfm, 3.5l tank

* the Badger dB rating comes from an online review, and notes that such numbers are measured in anechoic rooms; noise level in a real room will be higher.

** one online store lists the D3000R as nominally 30psi but up to 40psi "depending on airbrush".

The bigger the tank, the higher the pressure, and the farther min and max are apart, the less often the compressor will run. Some info on that:

- Badger TC910, min/max: 43/57psi, 28sec to refill tank from cutoff (one report)

- Iwata IS-975, min/max: 50/80psi

- Paasche D3000R, min/max: (note 1)

- Paasche DC600R, min/max: 43/57psi

- Sparmax TC-620, min/max: 40/65psi, 9 sec to refill tank from cutoff (one report)

Notes:

1. Paasche says the tank max is 50psi and the compressor will fill to that. Multiple store sites say it has an operating range of 20-40psi, but this may be a misreading of the spec sheet comment that it's operating pressure varies from 20-40 depending on airbrush used.

Iwata IS-975, dual regulator

Some Comments

One online comment comparing the TC910 and TC-620 was that the compressor on the TC-620 took less time to refill the tank and was quieter (but only a little). So you are getting some value there for the extra cost of the Sparmax.

Also, the Iwata and Sparmax compressors are both reportedly made by the same company in Taiwan: Ding Hwa, which has a good reputation. I haven't found much information on who really makes these units, and it may vary by model. And, of course, the same manufacturer can make very different models, depending on what the company selling them asks for, so the two aren't necessarily identical in detail.

I couldn't find anything about Paasche, except that they'd switched manufacturing of one model from Taiwan to mainland China (and the DC3000R instruction sheet says "made in China"), which doesn't necessarily mean the quality is worse if they manage it properly, but it could explain the lower costs for their equipment.

Badger's TC910 is also reportedly manufactured in China (rare for them, as most of their stuff is made in the U.S.), but the report didn't specify which China.

My local arts and crafts store sells the TC910, and while I'd love to support them, they sell it at list, which is US$100 more than the typical online price. I'm not willing to pay that much extra to support them; I'd rather put the money into a better model or a better airbrush. I could wait for a sale, of course, but the Badger isn't my first choice anyway.

The Paasche D3000R has a number of good reviews online, and you can't beat the sound level or cost. The downside is the pressure, which seems a bit low to me. I'd hate to discover that it works some of the time, but leaves me short someday.

The Iwata IS-875HT is interesting: the tank on this is actually the tubular handle used to carry the compressor. It's really just enough tank to help level out pressure fluctuations, and isn't going to let the compressor rest very much. I don't see this as attractive for my purposes.

The Iwata models are premium-priced since they're a "name" brand even among name brands. I still haven't figured out why the IS-900 costs more than the IS-975, as the latter seems to have more features. I saw a very good video review of the IS-975, which seemed pretty quiet for its nominal 55dB sound level. And being able to hook up two different airbrushes might be handy, but oh that price.

See some comments about noise levels on this thread. There’s also a video review of the Iwata there, which lets you hear the sound.

Summary

The Paasche DC600R or Badger TC910 seem like the most likely options, although the IS-975 has appeal despite the $175 cost difference (of course part of that is the second regulator, but I don't really *need* a second regulator). Some googling for user experiences didn't turn up anything negative about any of these brands, just a lot of positive comments. Given how prone the Internet is to negativity, that’s a strong statement of the quality of all three.

With the high sound rating on the Badger, I'm inclining to the Paasche at present. But I need to think on it some more, and likely do more research, before making a final decision.