Storing Rail

As I’ve mentioned previously, I’m going to be hand-building turnouts for the new layout, and possibly also hand-laying some of the track, although I’ll mostly use flex-track. But this means that I need to buy bulk rail. I’ve actually done this in the past, and one of the problems I’d had was that rail is easily bent. And once bent, it’s generally not usable. I needed a place to store rail where it could be kept straight. And I was likely to have more than one rail type or size, so I also needed a means to keep the different kinds separate.

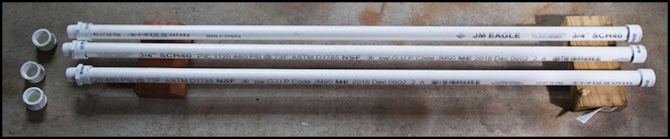

A friend suggested PVC pipe, which turned out to be a very good idea. A quick trip to the local hardware super-store revealed that 3/4” PVC pipe looked like a good size for storing a bundle of rail, and it comes in ten-foot lengths, which evenly subdivides into 40” lengths that will hold either 36” or one-meter (39.37”) lengths of rail. The store would even cut it for me. A solid cap on one end, and a threaded fitting on the other with a screw-on cap completed the design. I’ll probably eventually build a wood frame or rack to hold several of these tubes on a shelf or wall.

If I were hand-laying track and buying in large quantities, I’d probably use larger diameter pipes to store it. But for keeping a dozen or so rail lengths on hand for turnout assembly, this is a good size, and it limits the amount of motion the rail can have. I could have left one end open, but having a cap means I can carry the pipe around with rail in it. For example, I expect I’ll take these to the store when I buy rail, and transport it home in them, to avoid any risk of in-transit damage.

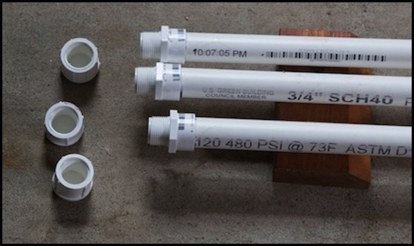

Note: like many things in the construction industry, pipe dimensions are misleading. A 3/4” pipe per “schedule 40” (what I bought) has an outside diameter just over an inch, and an inside diameter of 0.824” (20.9 mm). If you buy schedule 80 pipe (which apparently is gray rather than white) in the same size, the inner diameter is 0.742” (18.8 mm). Those inner dimensions are also “typical”, and I’ve seen other numbers listed for them. Finally, there are also some specialty types with other dimensions, but these are the two common forms. The exact diameter doesn’t really matter, but more is better for a storage container, so I recommend the white pipe.

Detail of end with pipe fitting

Gluing them was straightforward, but used a MEK (Methyl Ethyl Ketone) cement (technically a solvent, like ordinary plastic glue) that contained acetone, among other things. Very nasty stuff. I did it in a friend’s garage, with the window left open, using a “low VOC” formula, and even the next morning the odor was still strong. By 24 hours the odor was mostly gone. For a more detailed description of gluing PVC, there’s a good Instructable here.

Ideally you should clean and prime the PVC before applying glue, but since I don’t care about maximal structural strength or being water-proof, I just wiped dust off the pipe and applied the cement directly to both parts where they would touch. Work on one part at a time, and work quickly: you only have about 20 seconds after application before it dries (less in hot or dry weather). If there’s any force pulling the parts away from each other, hold in place for 30 seconds until it sets. The base cure time is 2 hours, so I did one end of each pipe and came back two hours later to do the other ends, so any fumbling about wouldn’t dislodge the first part.

MEK, as mentioned, is nasty stuff (see my Material Safety page for more info). You don’t want it on your skin, so wear disposable nitrile gloves. And even the fumes are considered to be carcinogenic, so you don’t want to breathe them. Use it outdoors or in some place where the fumes won’t get into the house (a shed or garage) and leave it to cure. And keep it away from anyone pregnant. And, of course, don’t eat, drink, or smoke while using it. Particularly the latter, as it’s highly flammable. Very nasty stuff.

Update: Just to be clear about how nasty MEK is: from what I’ve read online it will not only eat through nitrile gloves after a while, it will go through them and into your blood even before they dissolve. So wear gloves (or even double gloves), try to keep the MEK off them, and discard them after use.

Although cure time on the jar is listed as “2 hours”, it actually varies by the size of the joint. You can find cure-time charts by searching online. The one for my brand of glue noted that for a joint my size, at 20° to 40° C, typical cure time was 6 hours, but a full (180 psi) cure took 36 hours. These increase with humidity above 60%. I left the finished parts in the garage for a couple of days so they wouldn’t smell up my train room.

I may paint these, either to color-code different types of rail, or simply to make the shop look nice. Painting PVC is fairly straightforward, simply clean it with window-cleaner (anything with ammonia), sand lightly with 220 grit sandpaper to give it “tooth” for the paint to grip, then wipe any dust off with a damp cloth. Finally, spray it with a plastic-compatible paint. I’d probably use spray cans, as these won’t fit in my airbrush spray booth.

Multiple coats will likely be needed for a solid finish, and these need to be applied after the paint has partially dried, but before it sets (somewhere between 30 seconds and 5 minutes is probably good). Otherwise you need to wait a week or so to recoat to avoid crazing (cracks in the paint finish). Times will vary by brand.

Pro-tip: when painting, leave the cap off (you don’t want it painted on), wrap masking tape on the threads so you don’t gum them up, and stick a dowel inside the tube to use as a handle so you can paint the whole thing. I’m still working on what I’d use to hold the dowel while the paint dries. Maybe a board with holes drilled in it.

The parts cost excluding glue was US$10.20, and the glue sells for about US$5 for an 8 oz jar (good for about 275 joints; far more than I will ever need). So for about US$5 each, and about ten minutes of work, I now have three one-meter rail storage tubes. I expect I’ll make more of these.

Update: I don’t normally update the content of my musings, but this is worth mentioning: I’ve found that 1 inch schedule 40 PVC with similar fittings will hold a bundle of flex-track quite well. The only problem is that with the larger pipe there is more friction when attaching the fittings. I couldn’t get mine all the way on, leaving a lip where the ties could catch. I think the pipe needs to be sanded down slightly to allow a good hand-tight fit. Also, with the larger joints the glue will take longer to set, and I found the smell to persist at least a day longer.